The Ultimate Guide to Hydraulic Cylinder Troubleshooting and Repair Edit

Is your hydraulic system acting up? Are you dealing with leaky or bent cylinders or blown hoses? If so, you’ve probably had issues for a while that have been slowly lurking in the background, waiting for Murphy’s Law to hit you at the least convenient moment.

But what if you knew how to keep ahead of these issues?

At Jonestown Ag Supply, we recognize that failing or broken hydraulics can cost you time and money, affecting your bottom line and your reputation.

This blog will look at an overview of hydraulic cylinder repair. While we aim to be your go-to supplier and service provider for all things hydraulics and cylinder repair and supplies in East-Central Pennsylvania, we believe that a knowledge of hydraulics will provide you with the tools and knowledge to discern when something is about to break down, so that you can start the repair process before equipment breaks down, avoiding delays in work.

Are you pumped? Let’s get started!

Table of Contents

What Are Hydraulic Cylinders?

Hydraulic cylinders enable force and movement from construction equipment and manufacturing machines to aerospace and agricultural machinery.

They are a fundamental part of hydraulic systems, which use fluid power to perform work. The basic principle involves converting hydraulic energy into mechanical energy, allowing machinery to perform tasks like lifting, pushing, pulling, and pressing with significant force.

The Role of Hydraulic Cylinders in Machinery

Hydraulic cylinders are crucial in various machinery applications because they generate powerful linear motion. You can see examples of hydraulics in action on:

- Construction Equipment: Excavators, bulldozers, and cranes rely on hydraulic cylinders to manipulate booms, blades, push frames, and such to lift and move heavy loads.

- Manufacturing Machines: Presses, injection molding machines, and assembly lines use cylinders to apply precise force.

- Automotive Systems: Hydraulic cylinders are used in vehicles' braking systems, fuel, fluids, suspension, and steering.

- Aeronautical Systems: Hydraulic cylinders are critical for moving control surfaces on aircraft for lift, pitch, roll, and yaw, as well as landing gear and engine systems.

- Agricultural Machinery: Tractors and harvesters use cylinders for plowing, lifting, and other tasks.

Hydraulic cylinders' versatility and power make them indispensable in industries that require heavy-duty performance.

The introduction of hydraulic systems was critical in developing the heavy machinery that powered the Industrial Revolution.

Common Signs of Hydraulic Cylinder Failure

When a hydraulic cylinder fails, it can lead to machinery downtime, production delays, and increased maintenance costs. Understanding the causes of failure is essential for timely intervention and repair. Here are some common signs of hydraulic cylinder failure to look out for:

- Fluid Leaks: One of the most apparent signs of failure is hydraulic fluid leakage. The most common failure on hydraulic cylinders is that leaks can occur due to worn seals, damaged hoses, or cracks in the cylinder body. Hydraulic fluid leaks can be spotted by following the fluid leaking back to its origin. Most times even small leaks will wash the grime off from the leak point and downhill.

- Reduced Performance: A decrease in the cylinder’s ability to lift or move loads effectively often indicates mismatched components, internal wear, or damage.

- Unusual Noises: Squealing, knocking, or banging sounds during operation can signal internal issues such as air entrapment or component misalignment. Hydraulic cylinders are usually quiet machines, so any noise from your hydraulics should be taken seriously.

- Erratic Movement: If the cylinder moves jerkily or inconsistently, it may be caused by air in the system, improper hydraulic fluid viscosity, a malfunctioning control valve, or a damaged piston rod.

- Overheating: Hydraulic systems naturally generate heat when used, but excessive heat generation can result from fluid contamination, high operating pressure, or inadequate lubrication.

Troubleshooting Hydraulic Cylinder Issues

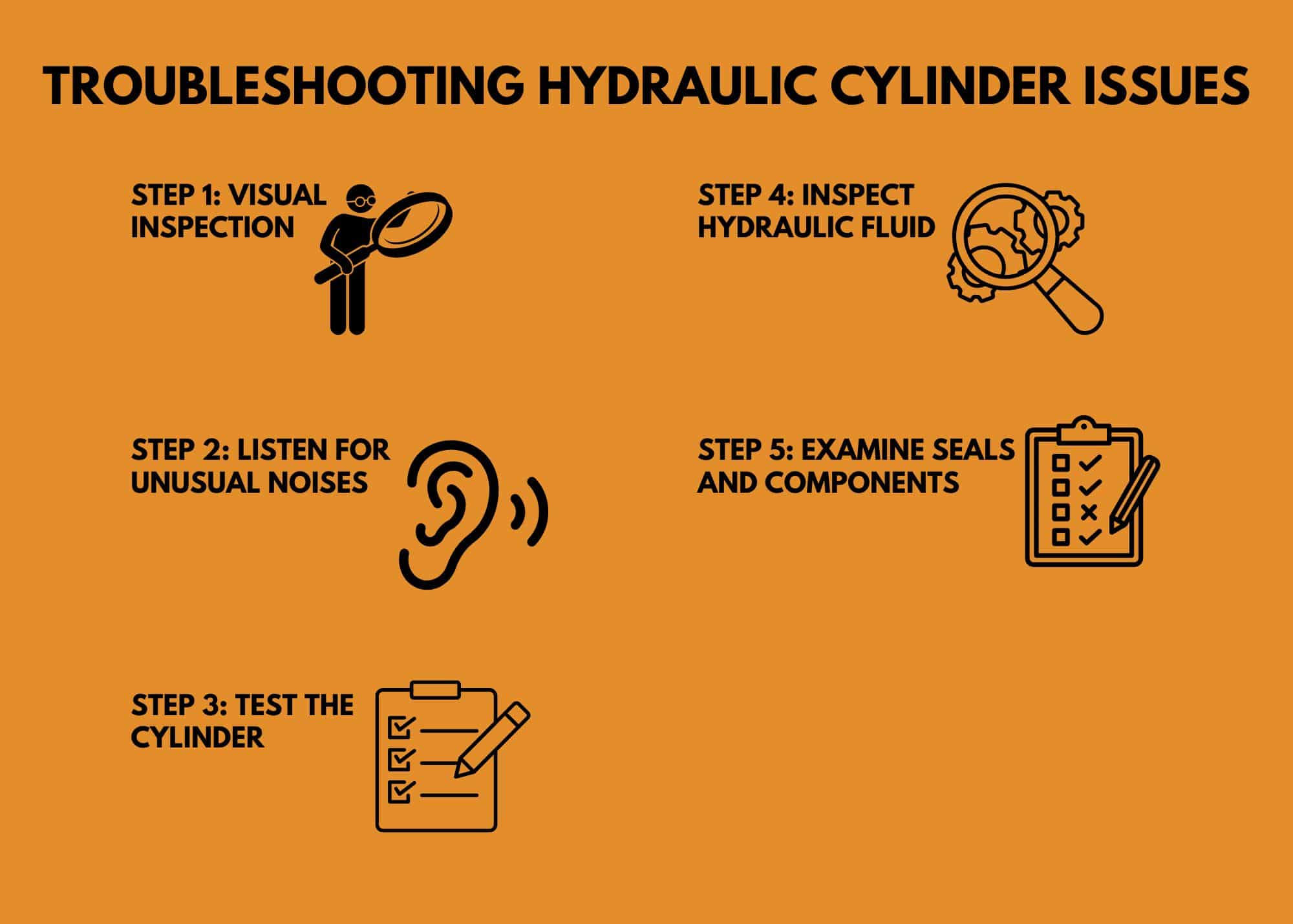

So you’ve got a faulty hydraulic cylinder. It’s annoying and likely costly, but before you call the service company, remember that a systematic troubleshooting approach may help identify and resolve the issue. Here are some steps:

Step 1: Visual Inspection

- Check for Leaks: Inspect the cylinder, hoses, and connections for visible signs of fluid leakage.

- Examine the Cylinder Rod: Look for signs of bending, scoring, or corrosion on the piston rod.

Step 2: Listen for Unusual Noises

- Identify the Source: Pinpoint where the noise comes from, which can help diagnose the problem.

- Check for Air in the Cylinder: Air in the system can cause noise. Bleeding the system might resolve the issue.

Step 3: Test the Cylinder

- Pressure Test: Conduct a pressure test to determine if the cylinder can maintain the required pressure without leaks.

- Movement Test: Observe the cylinder’s movement under load to identify any irregularities.

Step 4: Inspect Hydraulic Fluid

- Check Fluid Levels: Low or excessive fluid levels can impair cylinder performance and damage the assembly.

- Analyze Fluid Quality: Replace contaminated or degraded fluids at recommended intervals to prevent further damage.

Step 5: Examine Seals and Components

- Seal Condition: Replace worn or damaged seals, a common cause of leaks.

- Component Wear: Inspect for signs of wear on internal components such as the piston, rod, and barrel.

Of course, a trained professional should perform anything more than a quick troubleshooting routine. However, performing initial diagnostics and troubleshooting will save some time, and the information gathered can help the technician pinpoint the issue and get you back to work faster.

Preventative Maintenance for Hydraulic Cylinders

Any drill sergeant will tell you that properly maintaining a rifle is one of a soldier's most essential tasks. After all, a rifle is the soldier’s primary tool for his occupation. Without it, he can’t do his job.

The same goes for your equipment. Without properly functioning hydraulics, your farming or construction equipment will not be able to perform its task, and soon become a giant engine on wheels. At the same time, the driver goes from being a farmer or construction worker to just a regular guy with nothing to do. Regular maintenance is essential to minimize the risk of failure and extend the life of hydraulic cylinders.

Here are some preventative measures:

Routine Inspections

- Regular Checks: Schedule regular inspections to catch potential issues early, like seeing your doctor for your annual check-up.

- Document Findings: Keep detailed records of inspections and maintenance activities for future reference. A well-maintained log book records work performed and helps spot patterns over time when finding a solution has been challenging.

Maintain Fluid Quality

- Regular Fluid Change: Replace hydraulic fluid according to manufacturer recommendations to avoid contamination.

- Use Quality Fluids: Use high-quality hydraulic fluids that meet or exceed system specifications. These fluids are the lifeblood of your cylinders, so this is one area that you must not cut corners on!

Monitor Operating Conditions

- Avoid Overloading: Ensure the cylinder is not subjected to loads beyond capacity. It’s not just to avoid damaging the equipment, but it’s a good safety habit, too.

- Control Temperature: Maintain optimal operating temperatures to prevent overheating and fluid degradation. While hydraulic fluid typically heats up during operation, it’s designed to remain stable within specified temperature ranges during normal operating conditions. Overheating leads to deterioration of the hydraulic fluid, which will, in turn, degrade the performance and longevity of the cylinder over time.

Seal and Component Maintenance

- Seal Replacement: Replace seals periodically to prevent leaks and maintain pressure integrity. With the pressure inflicted on hydraulic cylinders, seals take the brunt of the pressure and are the first to go. A good technician will always inspect the seals to see whether or not there are leaks.

- Component Alignment: To reduce wear, ensure proper alignment of the cylinder and connected components. While internal component alignment requires a hydraulic specialist’s experience, external mounts can be quickly inspected and reported if there are issues.

Training and Education

- Operator Training: Educate operators on proper machinery use and the importance of regular maintenance.

- Maintenance Training: Equip maintenance personnel with the skills to perform thorough inspections and repairs. Investment in training, such as technical certifications and Lean methodology, will ensure that your equipment is in good hands.

Conclusion

We hope you’ve found this blog informative and helpful. As the old saying goes, knowledge is power, and it can help you save time and money by keeping your hydraulic cylinders operating in top condition.

Of course, some things require a professional, and we hope that this knowledge also helps you decide when to call in the experts at Jonestown Ag Supply to solve your hydraulic problems quickly. This, in turn, leads to better use of the technician’s availability and resources, and the resulting savings can be passed on to you.

At Jonestown Ag Supply, our goal has always been to provide the best parts and service to every customer while serving God and our local community, including being good stewards of your time and money! In addition to our hydraulic parts and services, we are your one-stop shop for power tools, truck bodies, trailer repairs, PTO repairs, snow plows, and more!

Contact or visit us today, and let us help your farm or business succeed!