Your Guide to Aluminum and Steel Truck Beds

Benjamin Franklin once said, “The best investment is in the tools of one's own trade.” A carpenter might invest in high-quality tools, while a writer might invest in courses or software to improve their craft. The same goes for truck beds—invest in a truck bed that’s engineered well and made with the right materials, and it will serve you well for years.

At Jonestown Ag Supply, we specialize in truck bed solutions for contractors, farmers, and DIYers. Our experienced team can help you select the ideal truck bed to fit your specific needs. One of the considerations with truck beds is material—whether an aluminum or steel bed is suitable for the job you need to do.

So, let’s explore the pros and cons of both types of truck bed materials and put this topic to bed!

Table of Contents

Durability and Strength: Which Material Holds Up Better Over Time?

The resilience of your truck is non-negotiable. While steel has the strength and ability to endure heavy loads and significant impacts, aluminum alloy, on the other hand, has an impressive strength-to-weight ratio, making it a strong yet lighter alternative.

Steel’s inherent strength generally makes steel truck beds more rigid and resistant to dents and scratches from heavy or sharp objects compared to aluminum. However, this rigidity can also be a limitation. Over time and under repeated stress, steel may be more prone to fatigue and cracking than the more flexible aluminum. Repairs to steel beds typically involve welding, a common and accessible skill in the agricultural community.

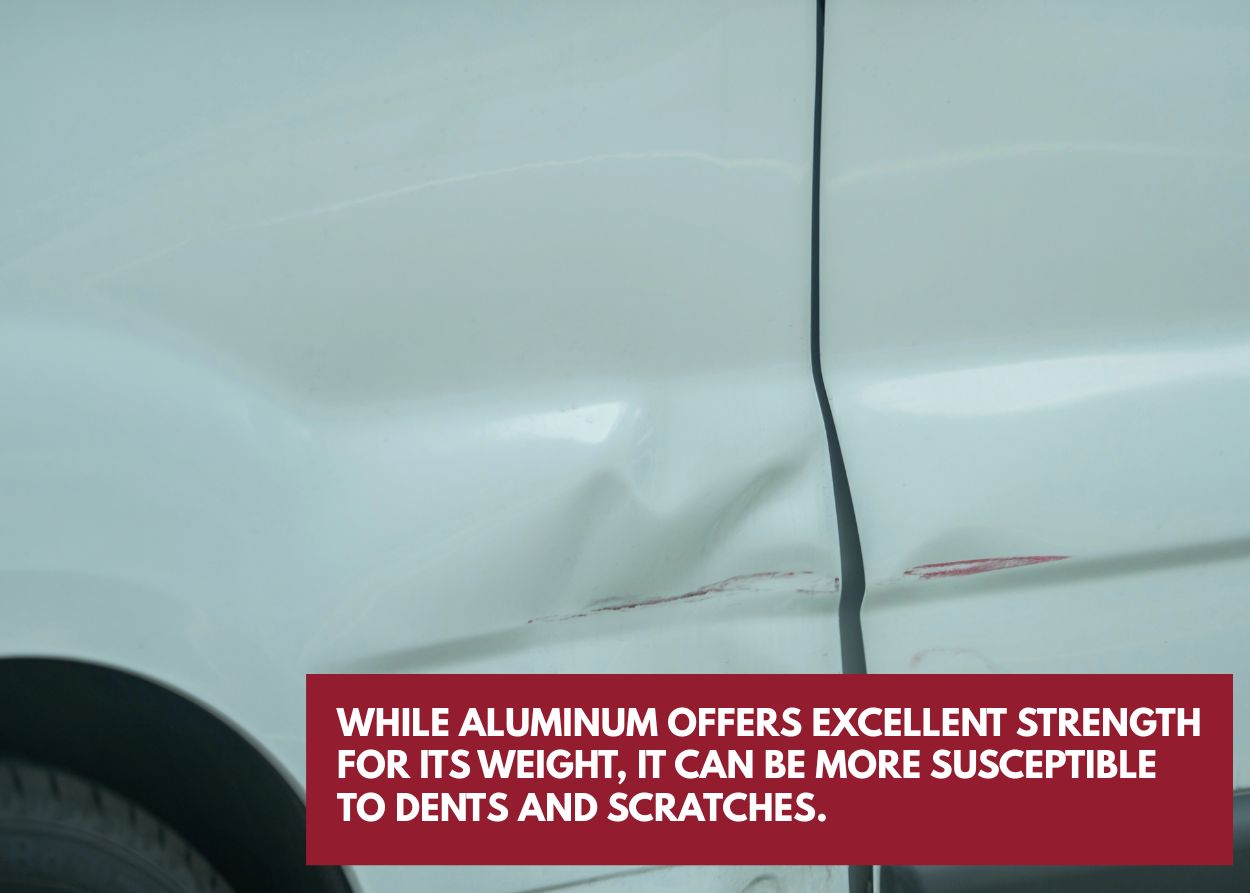

Modern aluminum alloys used in truck beds are engineered to withstand the daily demands of farm work. While aluminum offers excellent strength for its weight, it can be more susceptible to dents and scratches. Advancements in metallurgy have led to aluminum alloys, sometimes referred to as "military-grade," that can rival or even exceed the strength of some steel types. Repairing aluminum truck beds might require specialized welding techniques, but with the increasing use of aluminum in vehicles, more repair shops are equipped for this work.

So why choose one over the other? The specific tasks in your operation will determine which material proves more durable in the long run. Operations involving exceptionally heavy, blunt impacts might still favor steel's resistance to deformation. However, for general hauling and exposure to the elements, aluminum's flexibility and corrosion resistance could contribute to a longer overall lifespan.

Weight Differences: How Aluminum vs. Steel Affects Payload and Fuel Efficiency

While steel provides traditional toughness, high-strength aluminum alloys offer a compelling alternative, especially where a balance between strength and weight is crucial. Aluminum is considerably lighter than steel, often by as much as 50% for comparable sizes. An aluminum truck bed can be up to 40% lighter than a steel bed of similar strength. For anyone looking to stretch their operating dollars, this weight difference has substantial implications for payload capacity and fuel efficiency: You can haul more without exceeding legal limits, and your fuel costs are more justifiable.

The benefits of reduced weight extend beyond fuel and payload. A lighter truck body puts less stress on critical components like the engine, tires, suspension, and braking system. This can lead to extended lifespans for these parts and reduced maintenance and repair frequency, further contributing to long-term cost savings for your agricultural operations. Therefore, while the immediate advantages of increased payload and fuel efficiency are significant, the reduced wear and tear on the vehicle due to a lighter aluminum bed represent another important long-term benefit.

Corrosion Resistance: Which Truck Bed Lasts Longer in Harsh Conditions?

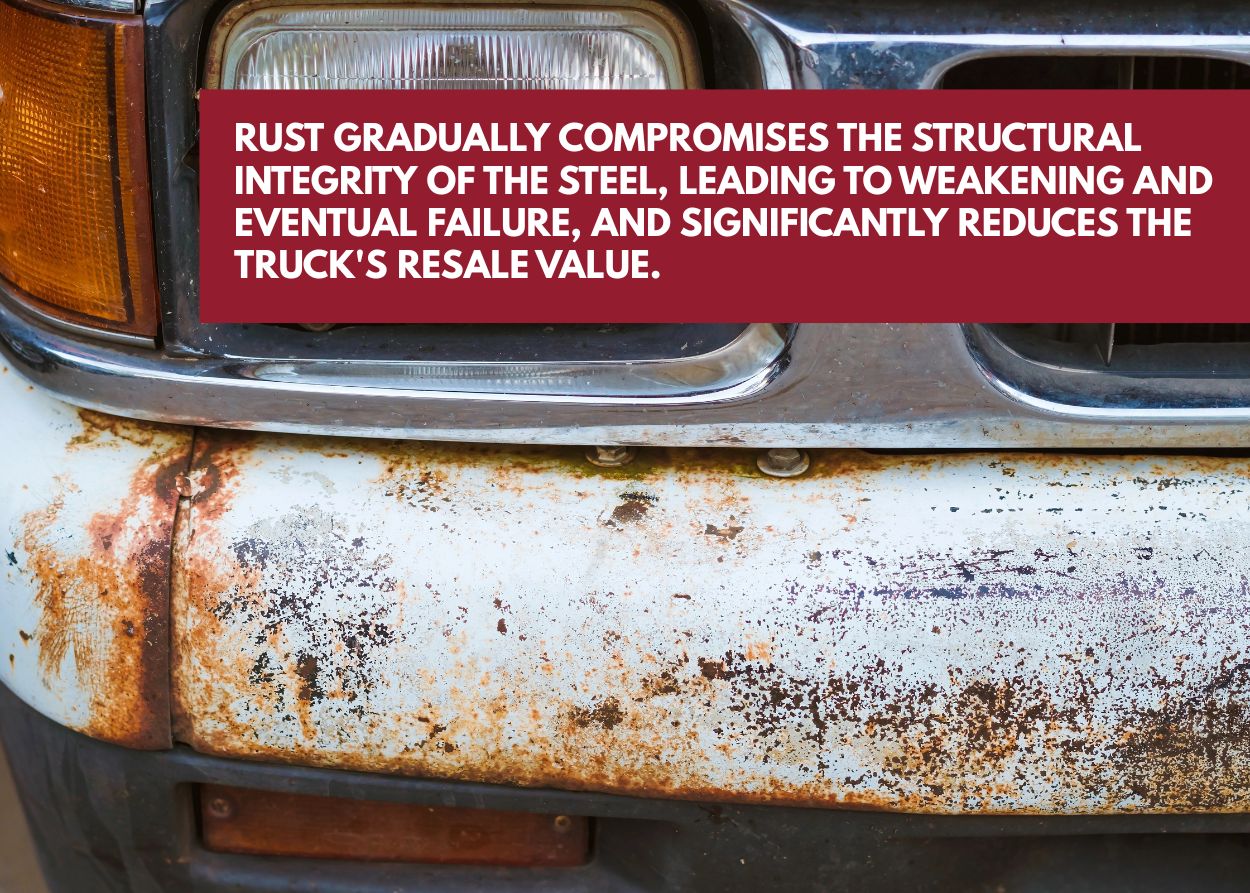

In the demanding environment of the workplace, where equipment is frequently exposed to moisture, fertilizers, debris, salt, animal waste, and various chemicals, corrosion resistance is a critical factor in the longevity of a truck bed. Steel is inherently susceptible to rust and corrosion, especially when protective coatings are scratched or damaged. Rust gradually compromises the structural integrity of the steel, leading to weakening and eventual failure, and significantly reduces the truck's resale value. While protective coatings like powder coating or galvanizing help mitigate rust, they require ongoing maintenance and can be compromised by the inevitable wear and tear of heavy use.

Aluminum alloys, in contrast, resist rust and corrosion. Its resistance stems from forming a protective oxide layer on the aluminum's surface when exposed to air. This layer acts as a barrier, preventing further oxidation and corrosion, making aluminum truck beds last longer and requiring less maintenance related to rust prevention. For agricultural operations, particularly those in coastal regions where saltwater can accelerate corrosion, marine-grade aluminum alloys offer an even higher level of protection. While aluminum is generally highly corrosion-resistant, it's not corrosion-proof under extremely acidic or alkaline conditions, which might be a consideration when handling certain specialized chemicals.

Cost Comparison: Upfront Price vs. Long-Term Savings

It's crucial to consider the potential for long-term savings when evaluating the overall cost-effectiveness of each material. Aluminum truck beds, while more expensive, offer several avenues for potential savings over their lifespan. The improved fuel efficiency due to their lighter weight can lead to significant reductions in fuel expenses, especially for vehicles that accumulate high mileage. The superior corrosion resistance of aluminum translates to lower maintenance costs, as there is less need for rust prevention treatments, repairs of rust damage, or repainting.

Furthermore, trucks with aluminum beds often command a higher resale value compared to rusted steel beds, allowing for a better return on investment when it's time to upgrade. The increased payload capacity offered by aluminum can also contribute to long-term savings by allowing for more efficient hauling and potentially reducing the number of trips required for specific tasks. While steel beds have a lower initial price, the potential for recurring costs associated with rust maintenance and higher fuel consumption should be factored into the long-term cost equation.

The Best Truck Bed for Different Industries and Uses

Choosing between an aluminum or steel bed depends on your needs. For general hauling purposes, both materials can be suitable. If lighter loads are the norm and fuel economy is a priority, aluminum is often the choice. However, if you’re consistently hauling heavy loads, a robust steel bed might be the best choice for dent resistance and rough handling.

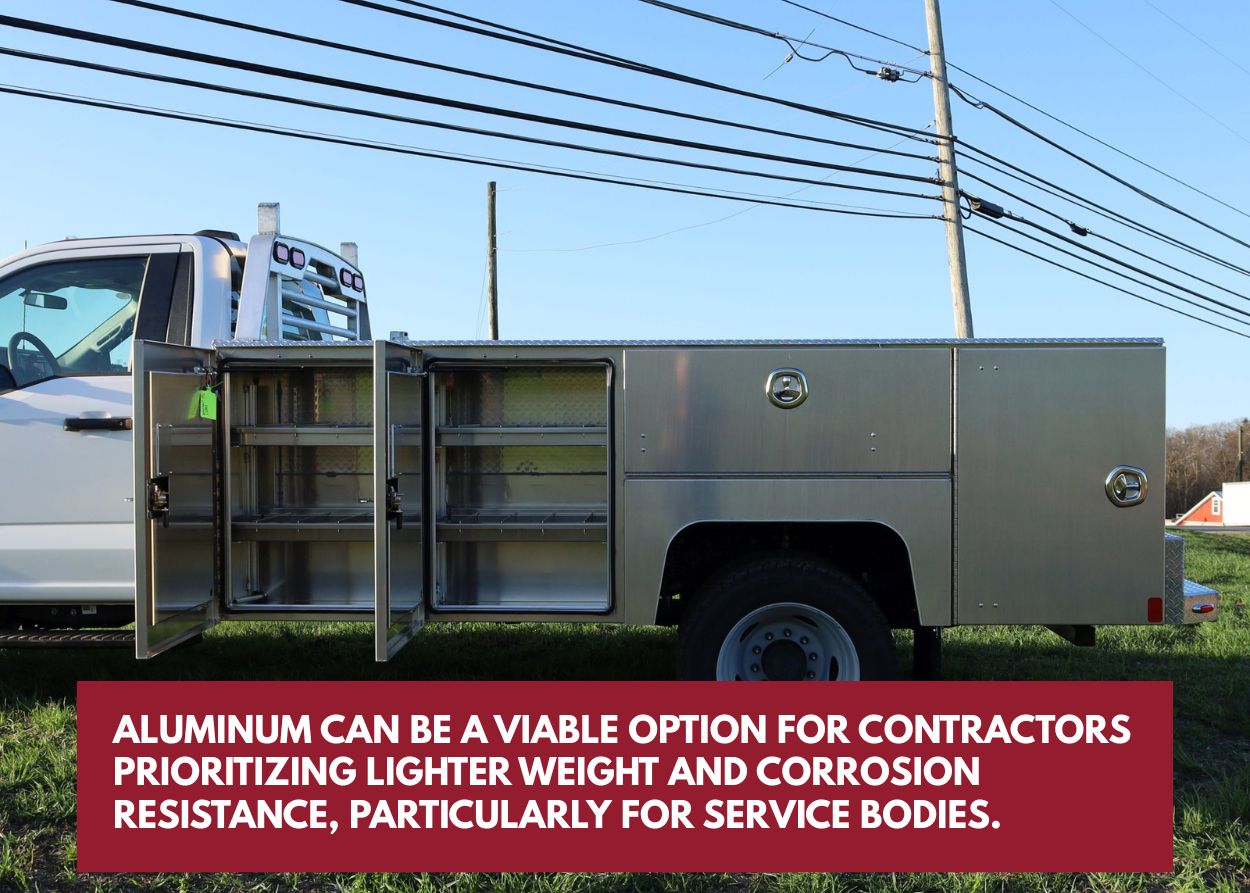

In the construction industry, steel truck beds are favored due to their ability to withstand the rigors of transporting heavy equipment, lumber, and other industrial supplies. However, aluminum can be a viable option for contractors prioritizing lighter weight and corrosion resistance, particularly for service bodies. Regardless of the material, it’s a good idea to install heavy-duty bed liners to protect the bed from the inevitable wear and tear caused by construction debris.

For agricultural work, the best choice often depends on the specific tasks involved. Steel truck beds are a traditional choice for heavy-duty ranch work, where durability and the ability to withstand the demands of livestock handling and rough terrain are paramount. However, aluminum is gaining popularity in agriculture due to its excellent corrosion resistance, which is particularly beneficial when dealing with fertilizers, animal waste, and consistently wet conditions. The lighter weight of aluminum can also be advantageous for fuel efficiency in large-scale farming operations.

Considering specific agricultural applications:

- Hauling Livestock: Steel beds with integrated gating and durable flooring are commonly preferred for their strength and the secure environment for transporting animals.

- Transporting Crops: Both aluminum and steel can be used, but aluminum offers an advantage in preventing contamination from rust, which could affect the quality of certain harvested crops. Tarp systems are crucial for protecting these loads during transport.

- Moving Equipment and Supplies: Steel's strength is beneficial for hauling heavy machinery and implements, while aluminum's lighter weight might be preferred for the frequent transport of lighter supplies like feed, tools, or fencing materials.

- Dump Beds: Both steel and aluminum dump beds are available. Steel options are often more economical for heavy-duty applications, while aluminum offers better corrosion resistance and increased payload capacity for materials like mulch, sand, or gravel. Bed liners can further enhance the functionality and lifespan of dump beds, regardless of the material.

Conclusion

Choosing the right truck bed material is a significant decision for any operation. Both aluminum and steel offer a range of benefits and drawbacks that warrant careful consideration. Steel truck beds are recognized for their inherent strength and lower upfront cost, making them robust and budget-conscious options for heavy-duty tasks. Still, their heavier weight and tendency to rust can lead to higher long-term maintenance and fuel expenses. Aluminum truck beds, on the other hand, have a higher initial price but offer significant advantages in terms of weight reduction, leading to improved payload capacity and fuel efficiency. Their natural resistance to rust and corrosion also means lower long-term maintenance costs and a potentially higher resale value.

At Jonestown Ag Supply, we carry a range of truck beds to meet the specific demands of your work, budget, and long-term ownership goals. Will you need rugged strength to carry heavy loads? We’ll set you up with a steel bed! Do you need to prioritize fuel efficiency, increased payload, and long-term rust resistance instead? We have aluminum beds for you, too!

Contact us today and talk to us about getting the perfect truck bed for your business!